Background

Dam Safety Intelligence(external link) (DSI) is a subsidiary of giant electricity company Meridian Energy. DSI is responsible for 12 staff and is New Zealand’s only specialist dam safety consultant. They cover the spectrum of dam owners, from very large, like hydro dams (including Meridian’s), to small, and from the old (100 years old) to relatively new (20 years old).

DSI helps to monitor and manage more than 100 dams, serving energy companies, water supply authorities, irrigators, and councils. Internationally, it monitors dams in Fiji and the Philippines and provides dam safety management services to clients in Australia, the United States, Canada, and Sweden.

Opportunity

DSI needed a system that was on a modern platform, using modern code and platform components. Other “off the shelf” offshore systems were trialed and assessed, but none had the breadth and depth of functionality needed or the necessary quality assurance and audibility.

Solution

DSI decided to rebuild their Dam Monitoring System (DMS) software with Catalyst, an investment of several million dollars and several years. The DMS software is the primary tool for:

-

data handling,

-

quality assurance,

-

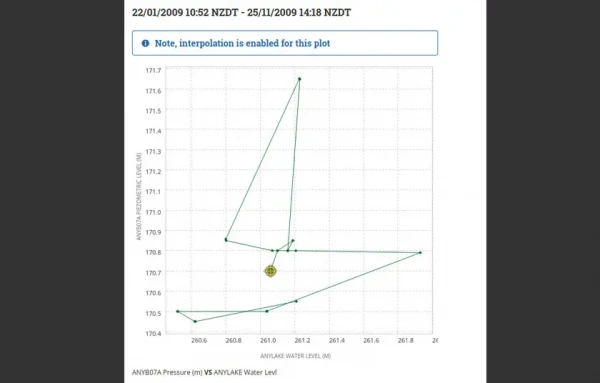

dam performance evaluation,

-

and reporting.

The rebuild focused on leveraging the principles and functionality of the legacy system out of various different modules. It ran on old hardware, using a relational database, in the Progress 4GL language back when screens didn't have a GUI (graphical user interface). Therefore, the graphs and plots were basic due to recording manual observations with hand-held data loggers.

The new system is cloud native. It uses the same sorts of structures as any scalable cloud product – containers, microservice architectures, and modern languages, with all the benefits these technologies bring:

-

scalability,

-

redundancy,

-

automated deployments,

-

and efficient use of cloud resources.

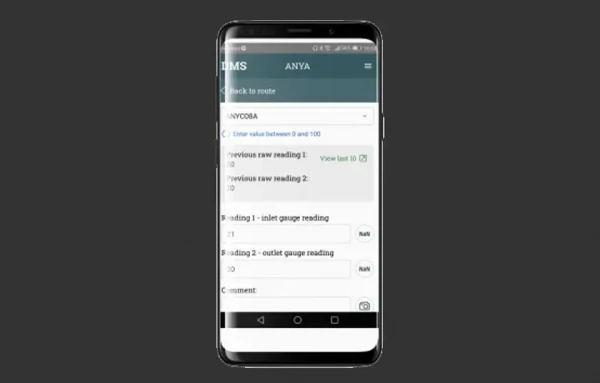

The system runs in the Catalyst Cloud(external link) and uses Kubernetes, Docker and Python. The interface is browser-based, so it works on smartphones and offline, so engineers in remote locations can log data when they return to areas with internet access.